ResinLab’s laboratory is equipped to characterize polymers and formulations including potting compounds and adhesives. These capabilities support new product development, technical service, and quality assurance. The laboratory team is also available for contract lab services and custom formulation consulting work.

Using the Hitachi TM3030 Tabletop Scanning Electron Microscope (SEM) with Bruker Energy Dispersive X-Ray Spectroscopy (EDX) attachment, ResinLab is capable of imaging samples at magnifications from 15 to 30,000x, including a chemical analysis of the sample surface – helpful for a variety of applications:

Test specimens must be solids.

ASTM: E1508, F1877

Our TA Instruments HR-20 Discovery Hybrid Rheometer can characterize a wide range of rheological properties. Our capability includes a thermoelectric Peltier plate which enables isothermal and programmed temperature schedules from 0 to 200 °C.

Properties include:

ASTM: D2196, D4473, D7836

ResinLab also utilizes the Gardco Gel Timer and Gardco Hot Pot Gel Timer to generate a gel time value for a 150 cc or 100 cc sample. The Gardco Hot Pot Gel Timer can cure at ambient room temperature, as well as elevated temperatures ranging from 65 to 175 °C.

The digital Brookfield DV-II Viscometer aids in measuring viscosity.

The TA Instruments Discovery DSC 250 Auto allows for full characterization of polymer formula cure and cured product thermal properties such as:

The temperature range of the instrument is -120 °C to +725 °C.

ASTM: D3418, D7426

Our TA Instruments Q400 Thermomechanical Analyzer (TMA) measures the dimensional changes of materials under conditions of controlled temperature, time, and force. The temperature range of the instrument is -50 °C to +350 °C. Test specimens should have parallel faces and will ideally be 1-10 mm thick. A small piece that is roughly 0.7 cm by 0.7 cm is the maximum size capable of sitting on the stage.

Properties that can be measured:

ASTM: E831, E1545

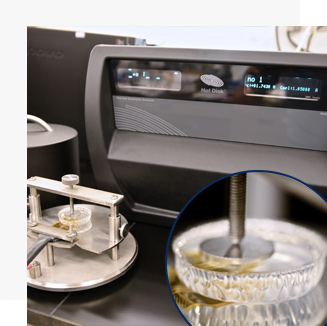

Our Thermtest TPS 2500S “Hot Disk” Analyzer measures thermal properties with high accuracy and reproducibility. Our current capability allows for testing of solids, viscous liquids / pastes, and powders at room temperature. In a typical test configuration, two identical specimens are tested, prepared as disc-shaped ‘pucks’ of material, and compress the thin-film sensor that both sources and senses during the measurement.

Properties include:

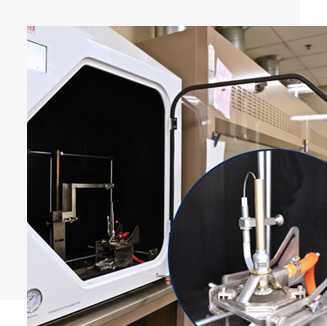

We also are equipped to perform UL94 testing, both vertical (UL94V) and horizontal (UL94HB) burn methods, with capability to cast bars at 3 and 6 mm. Please note that ResinLab is not a certified test laboratory, and UL certifications cannot be provided by ResinLab. These tests provide data that supports the pursuit of certification.

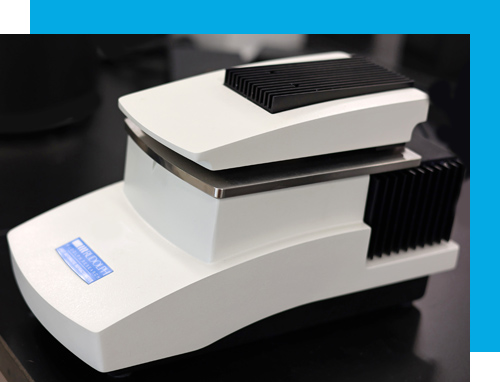

Our Nicolet iS10 Attenuated Total Reflection Fourier Transform Infared Spectrometer (ATR-FTIR) generates a fingerprint of a sample’s chemical functional groups. The ATR attachment enables non-destructive analysis of the sample.

Properties include:

ASTM: E1252

Our Instron 3369 Universal Tester measures a wide variety of properties across a full spectrum of materials including plastics, metals, ceramics, textiles, adhesives, elastomers, foams, and more. We also have an Instron 3119-615 Environmental Chamber with a temperature range of -100 to +350 °C. It is tall enough to allow for tensile testing of materials with a significant elongation to break.

Properties include:

We can measure a wide range of polymeric materials, including tough, high hardness epoxies and urethanes, and softer silicone elastomers.

ASTM: D903, D1876, D695, D1002, D3163, D638, D790, D624

We also have Shore Durometers in the D, A, and OO scales available to measure material hardness.

ASTM: D2240

Our Q-SUN Xe-1 Xenon Test Chamber simulates the effects of direct sunlight by providing light across UV and visible wavelengths in a controlled environment. Our chamber is equipped with a xenon arc lamp and Daylight – Q Filter, which correlates with the full spectrum of direct natural sunlight.

The Rudolph Research Analytical J457 Automatic Refractometers provide the capability to measure refractive indices of solid and liquid samples at wavelengths of 589 nm and 405 nm. Solid samples must be ½” in diameter and between 1-2 mm thick.

Our Jandel RM3000 is a 4-point probe that can measure electrical properties of both thin film and bulk materials, including electrically conductive adhesives.

It can be used for characterization of the electrical resistivity (conductivity):

ASTM: D2739

Our Keysight B2985A Resistivity Meter with 16008B Resistivity Cell can measure volume and surface resistivity of electrically insulating materials. Temperature and humidity are measured in tandem with resistivity. The test meter is specified for use from 0 to 55 °C at less than 70 % RH. Values are typically generated at a source voltage of 500 V. A typical sample size is a 4” by 4” square with a thickness of 3 mm. The two faces of the square should be as flat and parallel as possible.

Resistivity measurement ranges are as follows:

ASTM D257

Our Keysight E4908AL Dielectric Constant Meter and 16451B Test Cell measures dielectric constant (relative permittivity) and dissipation factor (tan delta). The test cell can be used at temperatures ranging from 0 to 55 °C. The test meter can provide measurements in the frequency range 20 Hz to 300 kHz. To generate accurate and reproducible results, the fixture requires disc-shaped specimens with thickness less than 10 mm, with 2 mm or less ideal, a diameter of 40 to 56 mm (1.6 to 2.2 inches), and surfaces as flat and parallel as possible.

ASTM D150

Our Phenix 4TCE100-10/D149 DC Dielectric Strength Tester measures the dielectric strength, or voltage required to generate failure, in insulating materials. We have Type 2 and Type 5 electrodes and a room-temperature oil bath with transformer oil that conforms to ASTM D3487 Type II. The unit can source voltages up to 100 kV with minimum ramp rate of 500 V/s. Samples must be thin and flat with parallel faces. When using the Type 2 electrodes, the specimen must be at least 2” in diameter. Each specimen must also be thin enough to fail within the maximum range of the unit, which usually corresponds to 2 mm or less thickness for the most highly insulating specimens.

ASTM D3755

For more information about our testing and characterization lab services, contact us today.